Although there is now less concern about its availability, the price of helium is set to continue to increase meaning that cost-effective alternatives are still attractive to analytical labs.

Many of the labs affected by the helium shortage of 2012-2013 have found that they are able to source helium readily although they have seen stark increases in price over the past 2 years. One direct consequence of the helium shortage was the increase in information made available to chromatographers about alternative carrier gases and the resulting increase in uptake of nitrogen and hydrogen as alternatives owing to a change in the perception of using these gases.

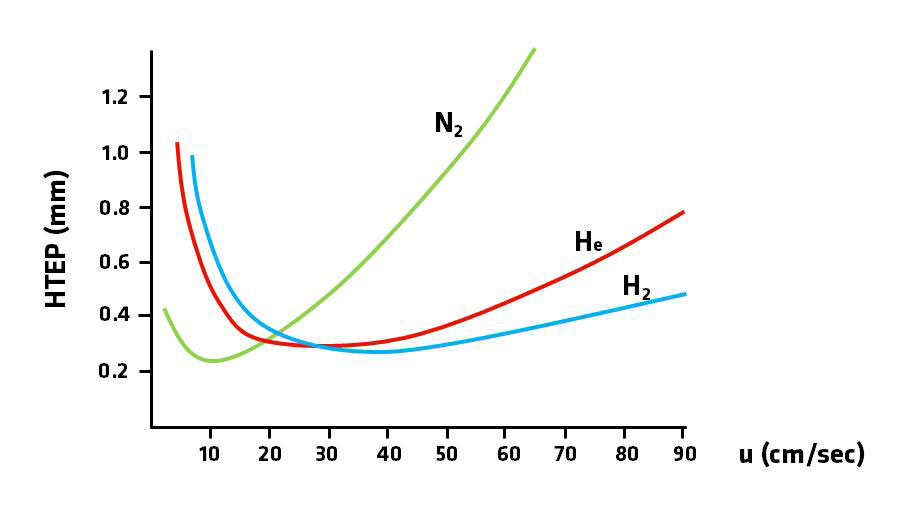

Nitrogen is seen as a slow gas and is often overlooked as an alternative to helium when its use would be perfectly valid in a number of GC analyses. With a low optimal linear velocity of 8-14 cms-1 for nitrogen, compared with 25-33 cms-1 for helium (Figure 1), analysis times will be increased if the analyst wants to maintain optimal performance. However, if there is enough resolution between peaks, it is possible to run samples at a higher average linear velocity, which will mean sacrificing some theoretical plates, which in practical terms will mean broadened peaks.

Hydrogen on the other hand is more efficient than helium at higher linear velocities, with an optimal linear velocity range of 38-45 cms-1, meaning that efficiency is improved compared with helium. This improved efficiency at higher linear velocities potentially allows for increased sample throughput, however it is not always possible to analyse a sample at a higher linear velocity because of lack of peak resolution. Matching the linear velocity of hydrogen to that of helium should mean like-for-like analysis, with slightly improved carrier efficiency.

One concern that people have with working with hydrogen is its flammability and placing hydrogen cylinders in the lab is a potential health and safety risk. Therefore the use of generators to produce hydrogen, and indeed nitrogen, is a cost effective and safe method of gas production within the lab. Hydrogen is produced by the electrolysis of deionised water and is supplied to the GC on-demand. The hydrogen generator contains only a low volume of hydrogen at much lower pressure than cylinders, whilst being able to produce enough gas to supply a whole lab. Nitrogen is produced by removal of oxygen, CO2 and hydrocarbons from compressed air by pressure swing adsorption using a carbon molecular sieve material.

A three-component alkane standard was run using a Shimadzu 2010 GC with a Restek RTX-1 column (30 m x 0.25 mm x 0.25 µm) using cylinder helium, and hydrogen and nitrogen produced by gas generators as the carrier gases. The samples were run isothermally (170°C) using the three carrier gases at the same linear velocity (37.5 cms-1) to look at the effect on peak area, peak width, theoretical plate count and resolution.

Figure 2 shows that the results obtained from this short run are very similar regardless of the carrier gas used. Hydrogen and helium give almost identical results, with the peaks in the nitrogen run showing a little band broadening and although the linear velocity of all 3 carrier gases was set to 37.5 cms, the alkane peaks run with nitrogen carrier are slightly delayed compared with the hydrogen and helium.

The data in table 2 shows that all three carrier gases produced the same peak areas for each of the three compounds so there was no effect of carrier gas on sensitivity. As expected, however, running nitrogen at a high linear velocity has the effect of reducing efficiency, which is shown in the lower number of theoretical plates and therefore reduced resolution. The reduced efficiency has the effect of broadening the peaks which is visible in the chromatogram and is shown in table 2.

For analysis of samples like the alkane mixture which has plenty of resolution between peaks, there would be no reason why nitrogen and hydrogen cannot be used instead of helium. Although use of nitrogen results in a reduction in theoretical plates, this does not impact on the overall results seen here. There is a strong case for using nitrogen for a number of GC analyses where high efficiency is not essential.

Hydrogen performed very similarly to helium and this demonstrates why a large number of labs are now moving their analyses from helium to hydrogen since they can get comparable chromatography, whilst using a cheap, readily available alternative to helium produced safely by hydrogen generators.

The price of helium is set to continue to rise for the foreseeable future so the results here show that nitrogen and hydrogen can be used as an alternative carrier gases without loss of performance. Production of these gases by generators means that labs have a constant, on-demand supply of gas free from the annoyance of running out of gas in the night or having to move heavy cylinders around.

Table 1. Peak areas, theoretical plate count, resolution and peak width of Decane, Undecane and Dodecane run with helium, nitrogen and hydrogen carrier gases.

|

Carrier Gas |

Helium |

Nitrogen |

Hydrogen |

|

Decane Peak Area |

54376.5 |

53528.2 |

52180.2 |

|

Undecane Peak Area |

54300.6 |

53250.6 |

52498.7 |

|

Dodecane Peak Area |

53348.4 |

52592.5 |

52025.9 |

|

Decane Theoretical Plates |

49352 |

37802 |

44631 |

|

Undecane Theoretical Plates |

74117 |

48585 |

68726 |

|

Dodecane Theoretical Plates |

102110 |

57467 |

101117 |

|

Decane Resolution |

13.715 |

11.409 |

12.987 |

|

Undecane Resolution |

21.542 |

6.973 |

20.497 |

|

Dodecane Resolution |

38.533 |

29.353 |

37.642 |

|

Decane Width |

0.140 |

0.126 |

0.135 |

|

Undecane Width |

0.131 |

0.177 |

0.149 |

|

Dodecane Width |

0.154 |

0.196 |

0.159 |

Figure 1. van Deemter curve showing the efficiencies of helium, nitrogen and hydrogen over a range of flow rates.

Figure 2. Chromatogram showing Decane, Undecane and Dodecane run using helium, nitrogen and hydrogen carrier gases.

To find out more about Peak Scientific's hydrogen, nitrogen and zero air Precision series generators for GC click here or contact us.