Why do you need DI water?

In the lab, precision and accuracy are essential. Every tool, every chemical, and every step must be carefully controlled to ensure reliable, and repeatable results. Water quality plays a crucial role in ensuring consistent quality of hydrogen production from gas generators, which can play a central role in applications such as gas chromatography.

For optimal hydrogen generation, deionized (DI) water is essential due to its exceptional purity. Free from impurities and contaminants, DI water ensures that the hydrogen production process remains uncompromised, by protecting the generator's proton exchange membrane (PEM) cell, yielding hydrogen of the highest quality.

Water quality directly affects hydrogen purity, which in turn impacts the accuracy of lab results. Impurities in water can contaminate the PEM cell, affecting the quality of hydrogen gas produced, and potentially compromising analysis.

To ensure the production of high-purity hydrogen and maintain accurate analysis, lab managers must carefully select the water used in their hydrogen generators. The use of deionized (DI) water is essential to ensure the high purity of generated hydrogen.

What is DI water?

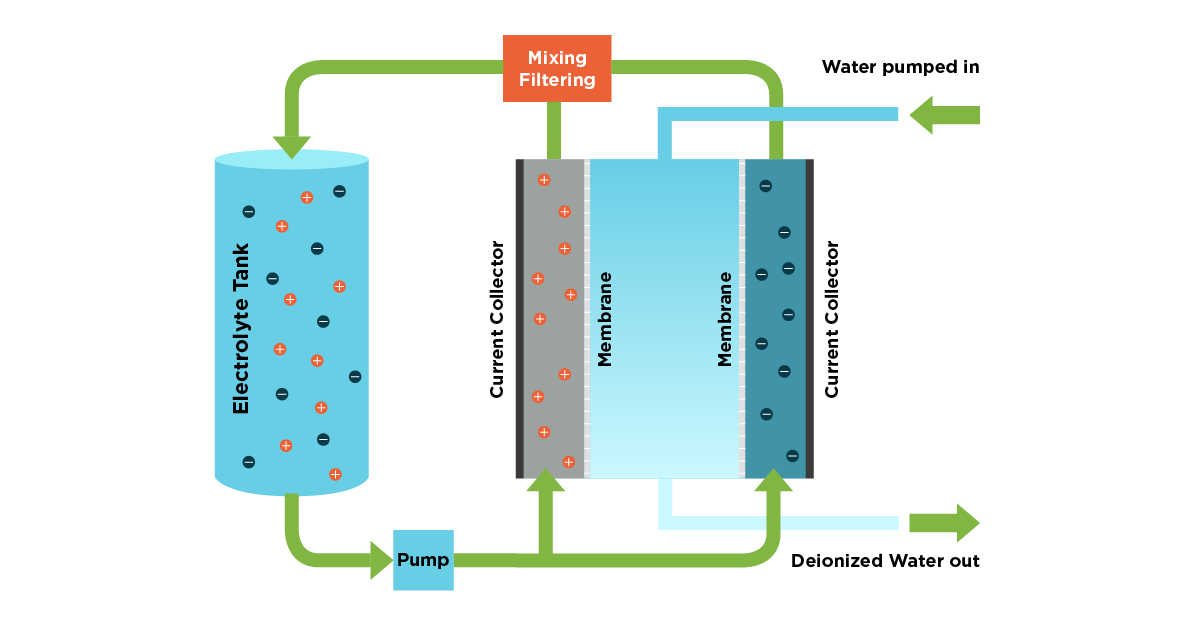

Deionized (DI) water is water that has had most of its mineral ions removed, such as cations like sodium, calcium, iron, and copper, and anions like chloride and sulphate. It is created by passing water through a deionizer, which uses ion-exchange resins to remove the charged particles.

DI water is the purest form of water, and it is used in a variety of applications, including hydrogen generation, battery production, and semiconductor manufacturing.

The role of DI water in PEM cells

PEM cells, also known as proton exchange membrane electrolyzers, are a cornerstone of hydrogen production technology. These devices harness the power of electricity to split water molecules into hydrogen and oxygen, a process known as electrolysis.

At the heart of a PEM cell lies a thin, semi-permeable membrane that catalyzes this remarkable transformation, and these membranes are particularly sensitive to dissolved ions.

DI water ensures the free movement of hydrogen ions through the membrane, allowing the electrolysis process to efficiently produce high-purity hydrogen. In comparison, distilled water has very few ions, making the electrolysis process very slow, resulting in less hydrogen being produced.

When using tap or distilled water, several issues can arise:

PEM cell damage: Poor-quality water will result in irreversible damage to the PEM cell as impurities are deposited on the PEM cell, reducing its active surface area and leading to the breakthrough of Oxygen.

Hydrogen Contamination: Oxygen breakthrough will significantly impact on H2 purity and instrument performance.

Increased power demand: As the PEM cell works inefficiently, it draws more power, increasing heat output and overall power consumption.

Poor-quality water can irreparably damage the PEM cell, leading to oxygen breakthrough, hydrogen contamination, and increased power demand. Use of incorrect water quality will void the warranty.

Selecting the optimal water supply

The choice of water supply depends on several factors, including the type of hydrogen generator, the desired hydrogen purity, and the budget constraints. While deionized (DI) water may require an initial investment in a deionization system, its benefits far outweigh this cost. DI water offers numerous advantages for hydrogen generation, including:

Hydrogen generator performance: DI water optimizes the performance of hydrogen generators, maximizing their efficiency and extending their lifespan.

Analytical accuracy: In laboratory settings, particularly in Gas Chromatography (GC), the purity of hydrogen used directly impacts the accuracy of analysis. DI water ensures that the hydrogen gas is free from contaminants, preventing interference with analytes and maintaining the integrity of analytical results.

Cost-effective: There are a range of deionization systems available and depending on the specifications, the initial investment may stretch your budget. However, the long-term benefits of supporting your lab with a good quality DI water purifier far outweigh the initial capital investment. By enhancing generator performance, minimizing maintenance costs, and safeguarding analytical accuracy, having a source of high-quality DI water can provide significant cost savings and quality assurance in the long term.

Enjoy steady workflows with a single tap

For uninterrupted hydrogen generator operation, consider a deionization system for your PEAK generators. Merck Millipore's deionization systems, such as the Milli-Q® 2 Series or Milli-DI® Water, are designed to provide a reliable supply of ultra-pure DI water.

With Merck Millipore's deionization systems, lab managers can rest assured that their hydrogen generators are operating at peak efficiency, producing high-purity hydrogen for their research and analytical needs.